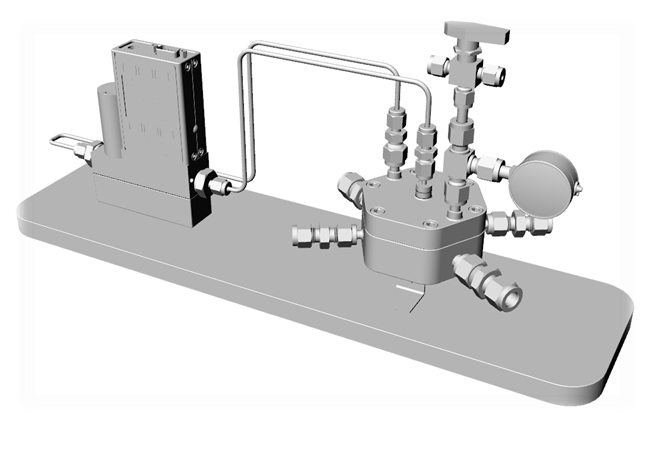

Back Pressure Regulator (BPR) with Integrated Quenching Unit

Precision. Control. Reliability.

.jpg)

Request a Quote

+91 73497 47401

Techne Avinya’s Back Pressure Regulator (BPR) with integrated quenching unit offers an advanced solution for managing pressure and temperature in flow chemistry, API manufacturing, fuel cell processes, and more.

With a high-precision control design, this unit ensures smooth operation and accurate monitoring, ideal for a range of industrial applications.

.jpg)

Key Features

What We Offer

Seamless Integration

The Back Pressure Regulator (BPR) integrates with an advanced quenching unit, ensuring smooth operation and optimal process control, even during pressure fluctuations.

Electropneumatic Precision

Paired with an electropneumatic controller for precise and smooth pressure regulation, ensuring consistent accuracy.

Temperature & Pressure Monitoring

Continuous monitoring of process fluid pressure and temperature with RTD sensors at both the inlet and outlet, providing real-time data.

Proven Reliability

The elastic member is tested to handle pressures up to 50 bar, ensuring long-term durability and minimal downtime.

Customizable Material Options

Available in materials like SS, Inconel, Hastelloy, and Titanium to suit a variety of environmental and application needs.

Contact-Free Temperature Sensors

Equipped with non-invasive temperature sensors for accurate monitoring of the process fluid at both the inlet and outlet, ensuring continuous system performance.

Contact

Need Help? Contact Us

Address

#148/A, Industrial Suburb, 1st Stage Peenya

Call Us

+91 73497 47401

Email Us

sales.techneavinya@gmail.com

Opening Hours

Mon-Sat: 9 AM - 6 PM; Sunday: Closed